ISO 9001 management responsibility

Any enterprise operating on the basis of modern management principles needs to define its objectives. The broad methodology for achieving these objectives in the form of a corporate policy. As has been seen in earlier chapters, quality is an important element in the success of an enterprise. A corporate policy document should therefore visibly demonstrate top management’s commitment to the quality of the products or services supplied by the company.

ISO 9001 Quality Policy

The ISO 9001 standard requires management formally to document its policy on quality, to ensure that this policy is understood by all concerned and to take appropriate steps to see that the policy is fully implemented. When defining quality policy, management should clearly state that one of the enterprises primary objectives is the full satisfaction of its customers because its very existence depends on continuing customer support. Quality building is a cooperative effort and cannot be achieved solely on the basis of orders or directives from the chief executive. It is necessary that the quality policy should be evolved with the participation and consensus of all concerned, and that it should take into account the enterprise’s background and culture, technological and market trends, as well as management’s long-term goals.

The quality policy of the organization should address some or all of the following :

- Product profile, i.e. type of products or services to be supplied;

- Identification of the market segment to be served and intention of satisfying customers.

- Approach to quality management.

- Involvement of employees in the quality-building effort.

- Compliance with statutory, environmental and safety requirements.

Organization

The standard needs that the authority, responsibility and interrelation of personnel who control, execute and verify work affecting quality should be described and documented. In principle, everyone’s work affects the quality of products and services supplied by the company in one way to another. The activities of groups or departments affect quality directly in some cases and indirectly in others. Therefore it is necessary to define the authority and responsibility of all groups for the proper establishment of a quality system.

For this it is essential to establish a formal organizational structure for the entire organization. This will also help in defining the interrelations of personnel who manage, perform and verify work affecting quality. Personnel in various departments and groups should have a clear understanding of their responsibility, authority and freedom of action, their channels of communication, and the means available to them for dealing with unforeseen situations. Each departmental employee needs to be conscious of his or her responsibility for achieving quality objectives.

Responsibilities

The broad responsibilities of various functional groups are given below :

Marketing

Conducting market research to establish the desired characteristics of the products.

Advertising and sales promotion.

Tendering and processing of orders and contracts.

Customer liaison and after-sales services, including handling of customer complaints.

Technical

Preparation of product specifications.

Design and development of products.

Process planning.

Development of tooling.

Development of process controls and specification of measuring and test equipment.

Production

Production planning

Deployment of production equipment and personnel and control of manufacturing activities.

Operation and monitoring of process controls.

Maintenance of plant and test equipment.

Preservation, packing and storage of finished products.

Materials management

Evaluation and selection of suppliers and subcontractors.

Acquisition or preparation of specifications for purchased products.

Processing of purchase orders.

Verification of purchased products.

Monitoring the performance of suppliers and subcontractors.

Storage of input materials and components.

Administration and personnel

General administration.

Defining qualifications of personnel and their recruitment.

Training and motivation of personnel.

Management of support services.

Finance

Financial management

Accounts

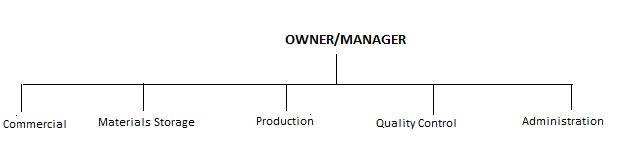

Organizational structure of small companies

The structure shown in the below figure is that of comparatively large organizations with well-defined departments carrying out the various operational functions. Most enterprises in developing countries are small or medium-sized. They would need to develop their organizational structures in such a way as to group functions in job packets that can be managed by a few executives or supervisors.

The ISO 9001 standard does not specify a particular organizational pattern, leaving enterprises free to organize their business to suit their needs. They may show functions separately in their organizational charts even though individual executives may control more than one function. Provided these functions or responsibilities are defined, the structure would meet the requirements of the standard.

Commercial Function

This contains activities like financial accounting, marketing and sales, and procurement of production inputs.Commercial activities are normally supervised by the owner with the assistance of a few other employees.

Materials Storage

This contains activities such as the receipt and storage of purchased materials and components, temporary storage of semi-finished materials, which in some cases may have to be sent outside for further processing and storage and dispatch of finished products. A separate space or godown is normally required for these activities. As they are related to the commercial function, these activities may be controlled by a supervisor in the commercial department.

Production

Production is the main activity of a manufacturing enterprise. The number of personnel and supervisory staff varies with the scale of operations and degree of automation. A manager with expertise in the relevant technology controls production.

Production activity include : planning and control of manufacturing operations, maintenance of process equipment and tooling, preservation and packing of finished products. In some cases, the production department may also be given the responsibility for the dispatch of finished products in accordance with instructions from the sales department.

Quality Control

In a small enterprise, quality control may be carried out by one or two persons with the requisite qualifications and experience. Activities include drawing up the quality plan and test schedules, inspection of purchased materials either on the vendors premises or on receipt at the company’s premises, in-process and final inspection, calibration of inspection and measuring equipment and assisting in the investigation of nonconformities and customer complaints.

Administration

This contains personnel management and training and general administration, including cleaning, security, transport and other support activities. In small companies, administration with its miscellaneous undefined functions is controlled by the owner-manager with the assistance of some staff in the commercial section. It is common to locate the office handling all commercial and administrative work in the immediate vicinity of the owners office. There is an increasing trend to subcontract services such as cleaning and security and transport, this reduces the administrative burden and ensures efficiency and economy. Training and general maintenance of the premises have a direct bearing on product quality, these functions should be well defined to comply with the requirement of the standard.

Provision of resources

The resource requirements in the 1994 version of the ISO 9000 standards have been extended to cover all resources for management, performance of work and verification activities. In the 1987 version of the standards, they were limited to verification resources.

It is obvious that specifying a set of quality requirements or issuing detailed instructions through manuals and procedures will not achieve the desired results unless adequate resources are provided for various jobs including verification. The broad categories of resources required for the implementation of a quality system are listed below :

- Suitable process plant and associated equipment/services.

- Adequate number of trained personnel.

- Well-designed process control equipment including gauges and measuring instruments.

- Input materials of the requisite quality.

- Provision of adequate time in the production schedule for the conduct of specified operations and verification activities.

We Solubilis, is the leading ISO Consultants provide various ISO Certification like ISO 9001, ISO 14001, OHSAS 1800, TS 16949, SA 8000, ISO 22000, ISO 15189, ISO 27001, ISO 17025 and all other major certifications in Chennai.